Advanced 3D Modelling and Manufacturing for Custom Insulation

Driven by continuous innovation Insulock’s ongoing investment in cutting-edge technologies—including 3D scanning, computer-controlled cutting, and premium specialist materials and threads—reinforces its position as the pioneer and market leader in custom-fit, removable Thermocover manufacturing.

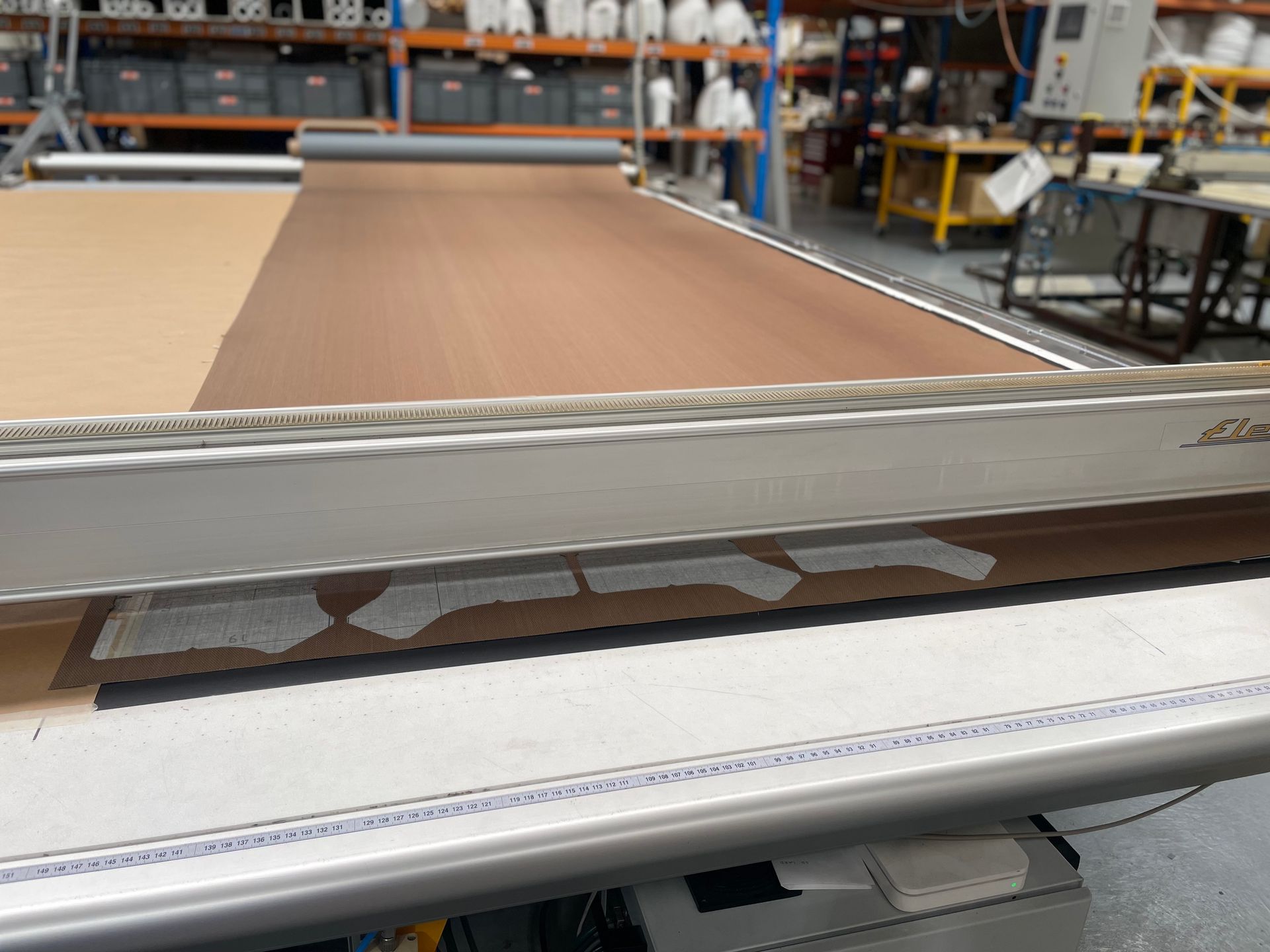

Precision Cutting for Optimal Insulation Fittings

Precision cutting enables insulation components to conform seamlessly to intricate shapes, minimising heat loss and enhancing energy efficiency across a diverse range of applications.

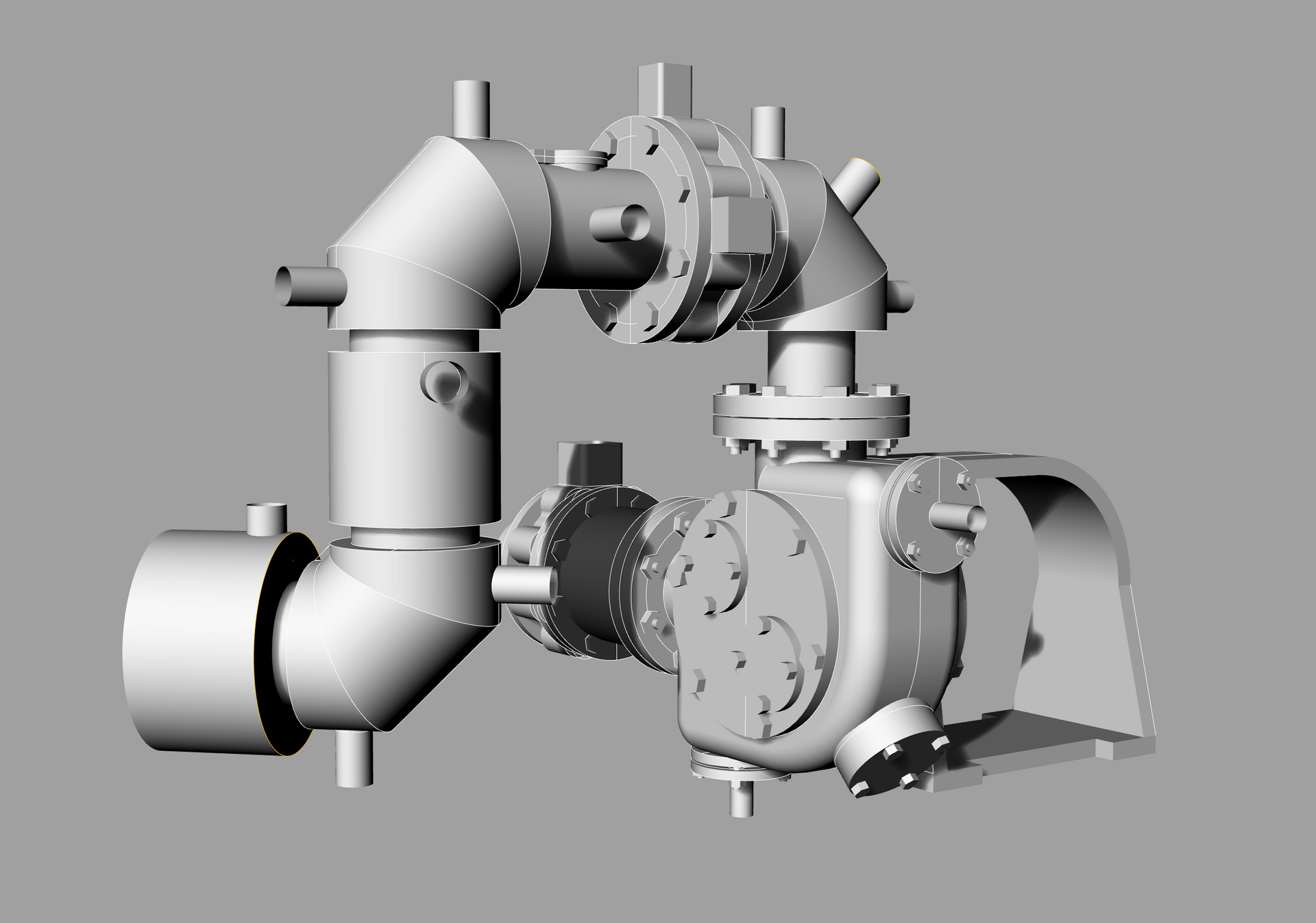

Our cutting-edge 3D scanning technology precisely captures the dimensions of equipment, allowing us to engineer insulation covers with a seamless fit. This precision minimises material waste and maximises thermal efficiency across a wide range of applications.

By combining high-resolution scans with advanced modelling techniques, we customise insulation solutions for intricate geometries and hard-to-access areas. This tailored approach not only boosts energy conservation but also streamlines installation and simplifies ongoing maintenance.

How 3D Scanning Shapes Tailored Insulation Solutions

Precision in every Cut

Get tailored insulation solutions with expert guidance

Contact Insulock for a personalized assessment to optimize your insulation needs.

Request a consultation

We will get back to you as soon as possible.

Please try again later.